Toyota 8 Series Forklift

Posted on

The Toyota 8-Series 1-3 ton engine powered

counterbalance forklift is engine-powered forklift model.

Stacked with world class safety features, superior performance, outstanding productivity and user friendly ergonomics, it's simply first class.

Built Toyota tough, the Toyota 8-Series 1.8 and 2.5 ton forklifts feature: exclusive System of Active Stability technology, Operator Presence Sensing safety system, Active Mast Function / Automatic Fork Levelling controls, and Wide View Mast for unparalleled visibility.

Comfort & Ergonomics

For outstanding ergonomic design

Toyota reexamined forklift operation with using the latest technology such as

motion capture technology. By using many rounded lines which have been rarely

seen in forklift built up, up to now Toyota has dramatically improved operator

space and ergonomics.

The side profile of the forklift reveals how the front and rear pillars are well rounded making the operator compartment more spacious than in any previous forklift.

The well rounded that flow from body to pillar

give a sense that the body and pillar are unified, also the entry space has

been enlarged since the seventh series, making the operator easier to enter and

exit.

The step has been also lowered and it

has been widen this decreases the effort to enter and exit the cabin.

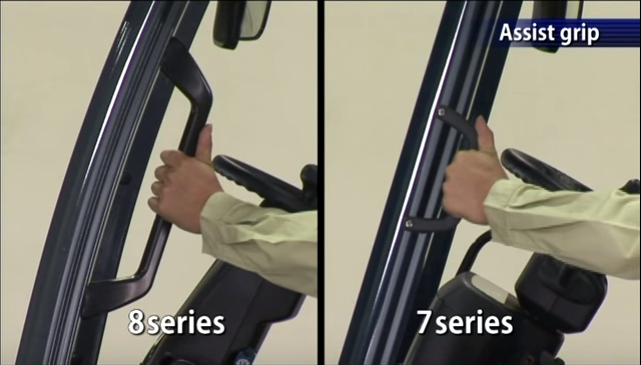

12 inch long dual operator assist

grips have been designed to meet the needs of varying operator sizes.

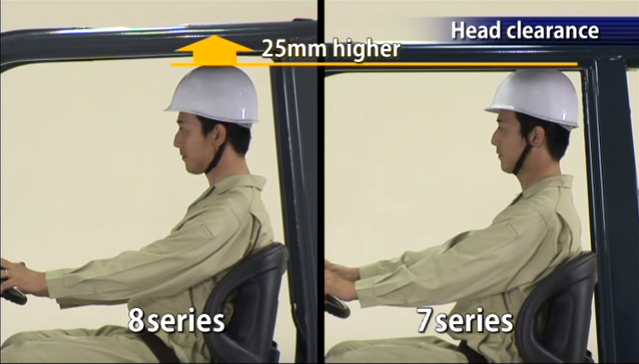

Inside the operator compartment head

clearance has been widen, the roof is 25 mmm higher than in the seventh series.

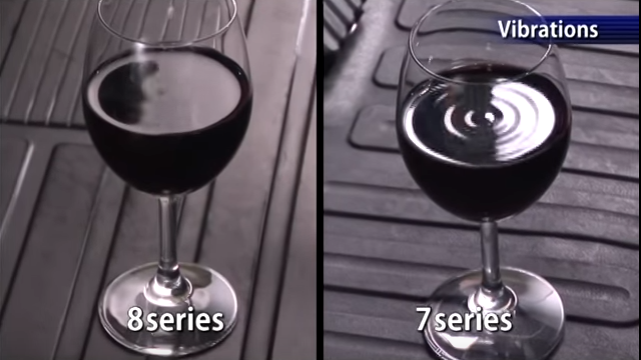

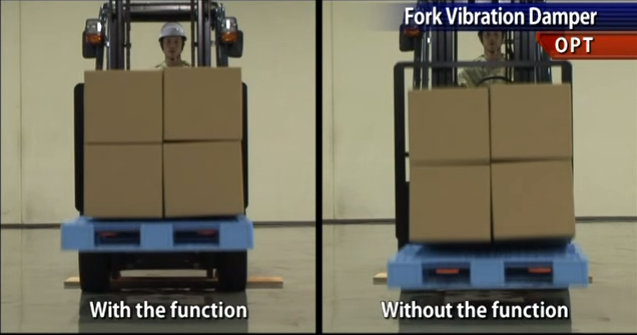

Vibrations have also been reduced by a third at the steering wheel, helping to provide a comfortable environment. Vibrations when transporting loads can make those loads damaged, with the Fork vibration Damper it helps to secure the load.

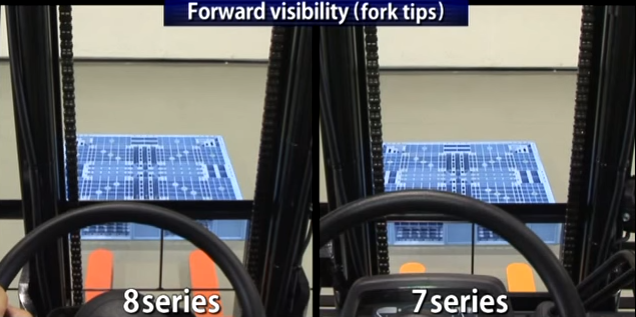

Outer mast middle beam has been

lowered so it does not abstract the operators view.

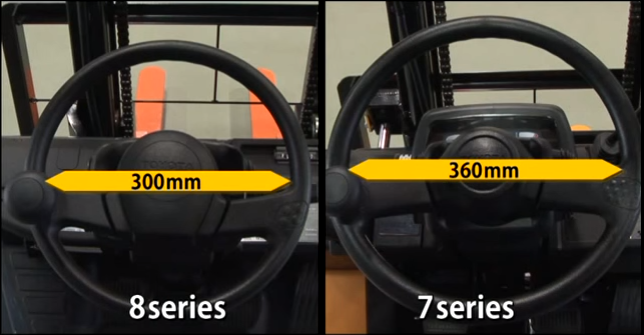

The steering wheel diameter has been

reduced from 360mm to 300mm, the display panel has been moved and the dashboard

has been lowered. These changes ensure better visibility that enables the

operator to see the fork tips clearly.

The upper view has also been improved

the head guard shape has been redesigned to decrease the area that blocks the

upward view.

On the power shift transmission models a foot activated parking brake comes standard, this enables the operator to engage the parking brake without changing posture.

Multifunction display, the display

provides low speed setting and maximum speed limit limitation it also provides

warnings and status information such as the maintenance hour meter and the

transmission temperature in a clear easy to read display. In addition the

operator can check the load weight by one simple click.

This helps the operator

from over loading the truck.

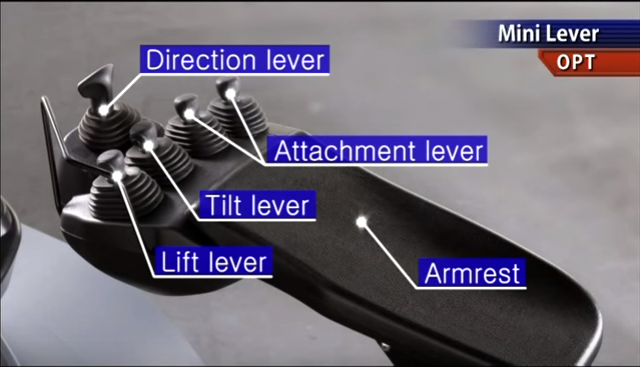

Mini lever that has small easy to

operate levers provide effortless load handling situations and travel direction

selection, a fatigue arm rest also has been attached.

The new optional joystick allows to do lift and tilt operations simultaneously.

Outstanding reliability and serviceability

Reliability is what Toyota forklifts always provided even under harsh conditions. With the eight series reliability and serviceability have been further enhanced for minimizing the forklift downtime and repair costs.

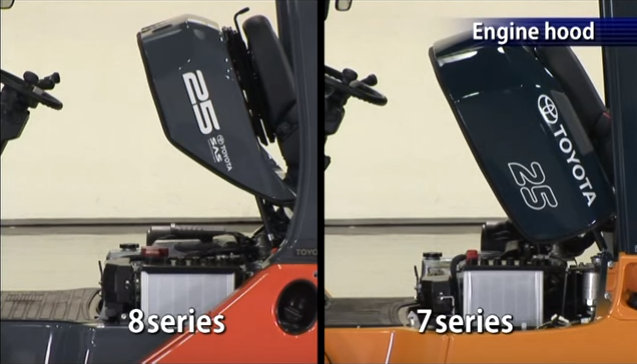

Engine hood now opens at a wider angle the hood has been slimmed down to improve accessibility to the engine compartment.

Water resistance in the electrical system has been enhanced, waterproof connectors are used on almost all electrical components and ESU and relays are now housed together inside a box so that heavy rain and other harsh condition don’t effect the eight series from providing service.

The cooling system efficiency has been improved, the fan and radiator layout has been optimized.

Excellent Safety

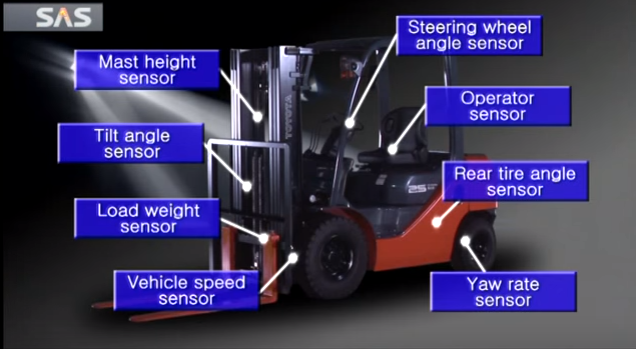

Toyota SAS monitors key forklift

operations, detecting and counteracting instability to help reduce the risk of

tip-overs.

When it senses instability, the Active Control Rear Stabilizer locks the rear axle to help reduce lateral tip-overs

Active Mast Function Controller senses and reacts to instability by limiting mast angle and speed according to the load's height and weight.

The Operator Presence Sensing (OPS) system helps to prevent accidental movement of the forklift and forks when the operator is not seated at the controls. The OPS system senses if the operator is properly seated and at the controls by means of the seat switch. When the operator is properly seated at the controls the seat switch will go "on".

If the operator is not seated at the controls the seat switch will turn "off", and the OPS system will disable the ability to lower the forks, or tilt forward or back along with all the other loading and unloading movements.

Our Products:

Contact Sourcefy:

Address:#108-209 Glen Cove Rd

Carle Place, NY

United States 11514

Email: support@sourcefy.com

Toll-free: 1-855-585-4430

Loading... Please wait...

Loading... Please wait...