How to Choose Pallet Jack Wheel?

Posted by on

Selecting the right pallet jack wheels is crucial for enhancing industrial operations and ensuring smooth workflow. These wheels are the foundation of pallet jack efficiency, key in maneuverability and durability. Whether you are considering pallet jack wheel replacement, looking for pallet jack rubber wheels, or exploring options for electric pallet jack wheels, understanding the variety and specifications of these components is key.

This guide aims to examine the process, covering everything from pallet jack replacement wheels to electric pallet jack wheel replacement. We will explore different types of wheels, such as pallet jack front wheels, load wheels, and even specialized pallet jack tires. Our objective is to equip you with the knowledge to make an informed choice, ensuring that the wheels for your pallet jack perfectly align with your industrial needs.

Basics of Pallet Jack Wheels

Pallet jack wheels are critical components that dictate how effectively a pallet jack can transport loads across various environments. These wheels come in various types, each tailored to specific operational needs.

For instance, pallet jack front wheels, primarily used for steering, differ significantly from pallet jack load wheels, which bear the bulk weight.

Options like pallet jack rubber wheels are chosen for their smooth operation and noise reduction qualities, ideal for indoor settings. On the other hand, electric pallet jack wheels are designed to accommodate the additional weight and functionality of electric pallet jacks.

Knowing when to replace these wheels, such as opting for pallet jack wheel replacement or electric pallet jack wheel replacement, is vital to maintaining your equipment's efficiency and safety. Each type of wheel, whether pallet jack replacement wheels or pallet jack tires, plays a unique role in ensuring the pallet jack operates smoothly, efficiently, and safely in its intended environment.

Types of Pallet Jack Wheels

Pallet jacks come with various wheels, each crafted from materials that cater to distinct operational requirements. Knowing these wheel types is crucial when you use a pallet jack, as it helps you make informed decisions about purchasing new wheels or replacing the old ones for optimal performance.

- Rubber Wheels: Pallet jack rubber wheels are known for their smooth operation. Rubber is a material that can easily roll over different surfaces without much noise. These wheels are great for indoor use where noise reduction is important.

- Nylon Wheels: These wheels are made from a strong plastic called nylon. Nylon wheels are hard and durable, making them suitable for carrying heavy loads. They work well on smooth, flat surfaces.

- Polyurethane Wheels: These wheels are a mix of rubber and plastic. Polyurethane wheels are tough like plastic but roll quietly like rubber. They are good for both heavy loads and smooth rolling on various surfaces.

- Electric Pallet Jack Wheels: Electric pallet jacks, which are battery-powered, have specialized wheels designed to handle extra weight. These wheels are often made of materials that can withstand the heavy-duty operation of electric pallet jacks.

- Steel Wheels: Steel wheels are the strongest. They are perfect for very heavy loads and industrial environments. However, they can be noisy and might damage softer floor types.

The material of the pallet jack wheels affects how well the pallet jack works. For instance, rubber wheels might not be the best choice for very heavy loads, but they are great for regular use in a warehouse. On the other hand, steel wheels can carry more weight but might be too tough on some floors.

Factors to Consider When Choosing Wheels

When selecting the right wheels for your pallet jack, it's important to consider several key factors. These include the wheel material, size, and the load capacity they can handle. Each of these elements plays a crucial role in the efficiency and lifespan of your pallet jack.

Wheel Material

The material of the pallet jack wheels, such as rubber, nylon, or steel, plays a key role in their durability and suitability for different environments. Rubber wheels are quieter and better for indoor use, while steel wheels are durable for heavy loads but might be loud and harsh on certain floors. For electric pallet jacks, the wheel material must accommodate the extra weight of the motor.

Wheel Size

Size is crucial for maneuverability and load distribution. Larger wheels can handle bumps and uneven surfaces better, making them suitable for heavy or irregular loads. On the other hand, smaller wheels offer better control in tight spaces. Always match the wheel size with your pallet jack's requirements, especially when considering pallet jack wheel replacement.

Load Capacity

This refers to how much weight the wheels can support. Pallet jack load wheels need to withstand the full weight of the loaded pallet without failing. Choosing wheels with the appropriate load capacity is necessary for safety and efficiency, especially for heavy-duty or electric pallet jacks.

Cost Considerations

The price of pallet jack wheels varies depending on the material and quality. While it might be tempting to choose cheaper options, investing in quality wheels can save costs in the long run due to less frequent replacements and maintenance needs. Balancing quality with budget is key when selecting pallet jack replacement wheels or electric pallet jack wheel replacement.

Compatibility with Pallet Jack

Ensure the wheels are compatible with your specific pallet jack model. This includes not only size but also the mounting and fitting requirements. Using the wrong type of wheels, such as electric pallet jack wheels on a manual pallet jack, can lead to inefficiency and potential safety hazards.

Standard Dimensions

The standard dimensions of a pallet jack typically include a width of 27 inches and a length of 48 inches. These dimensions are crucial when selecting the right wheels, as they dictate the size and type of wheels that will best fit and function with the pallet jack.

Choosing the appropriate wheel size for pallet jacks with these standard dimensions ensures proper balance, stability, and maneuverability.

Whether you're considering pallet jack wheel replacement or selecting new wheels, keeping these standard dimensions in mind is key to ensuring your pallet jack operates efficiently and safely. Remember, the right fit is not just about the wheel's diameter but also its width and compatibility with the pallet jack's size.

Replacement and Maintenance

Replacing and maintaining the wheels of your pallet jack is crucial for its longevity and efficiency. Here's a simple guide on how to replace pallet jack wheels and tips for maintaining them:

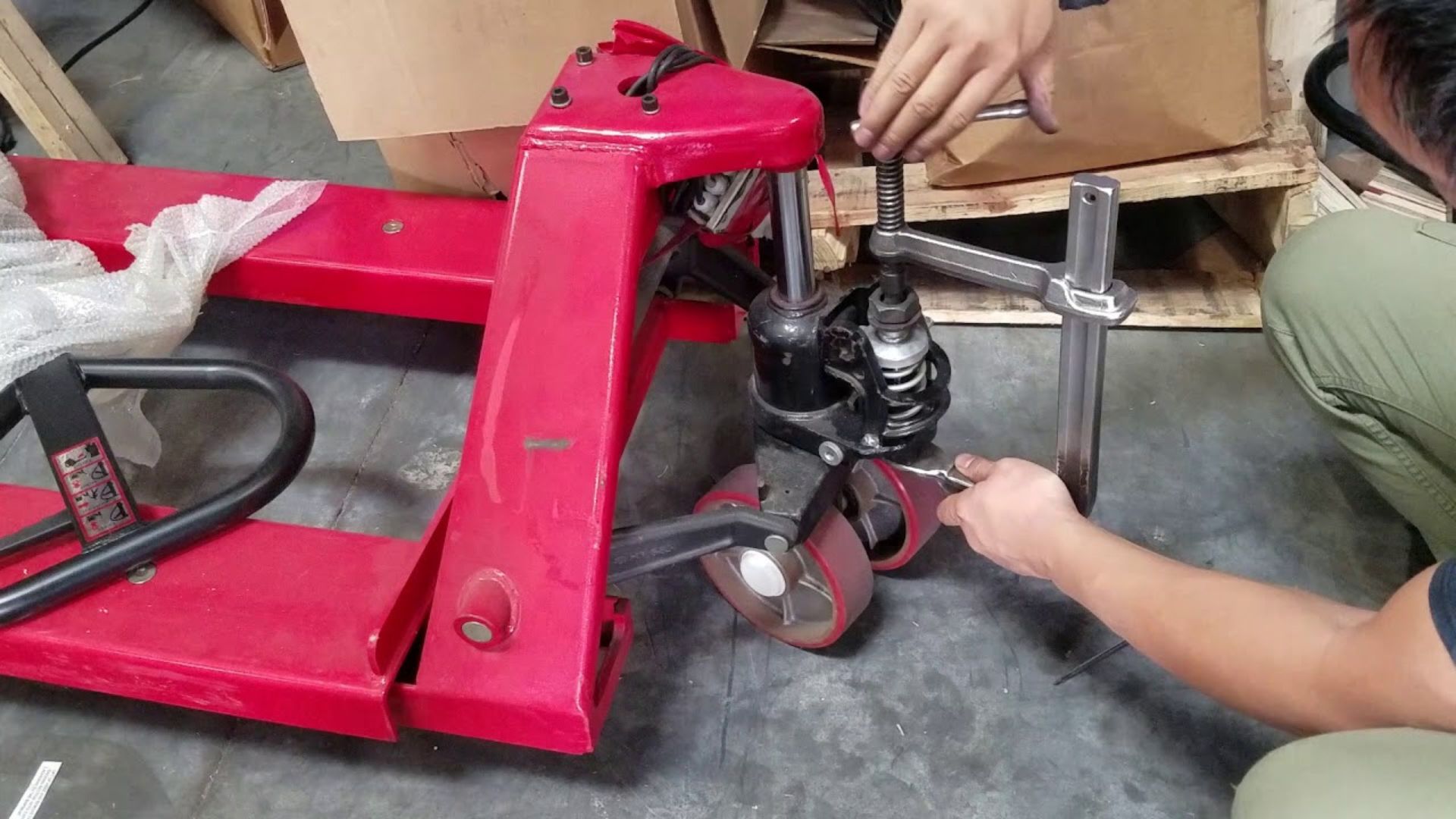

Steps to Replace Pallet Jack Wheels:

- Identify the Wheel Type: Determine whether you need to replace the pallet jack front wheels, load wheels, or both. This depends on the wear or damage you observe.

- Gather the Right Tools: You'll need basic tools like a wrench and a screwdriver. Depending on the model, you might need additional tools for electric pallet jack wheel replacement.

- Remove the Old Wheels: Use the tools to loosen and remove the bolts or nuts holding the wheels in place. Carefully remove the old wheels, whether they are pallet jack rubber wheels, electric pallet jack wheels, or other types.

- Install the New Wheels: Place the new wheels in the correct position, such as pallet jack replacement wheels or pallet jack tires. Secure them firmly with the bolts or nuts.

- Test the Pallet Jack: After replacing the wheels, test the pallet jack to ensure the new wheels are functioning correctly and the jack moves smoothly.

Tips for Maintaining Pallet Jack Wheels:

- Regular Inspection: Regularly check the condition of the wheels, looking for signs of wear, damage, or misalignment.

- Clean the Wheels: Keep the wheels clean from debris and dirt, which can cause damage over time. This is especially important for pallet jack load wheels, which bear most of the weight.

- Lubrication: Apply appropriate lubricants to the wheel bearings and moving parts. This is crucial for pallet jack wheel maintenance, including electric pallet jack wheels.

- Avoid Overloading: Do not exceed the load capacity of your pallet jack, as this can strain the wheels and lead to premature wear.

- Professional Checkups: For complex issues, especially with electric pallet jack wheel replacement, consider seeking professional help to ensure safe and correct replacement.

Conclusion

Understanding the various aspects of pallet jack wheels is crucial for ensuring your equipment functions optimally. Whether you're considering pallet jack wheel replacement, looking into pallet jack rubber wheels, or exploring options for electric pallet jack wheels, each decision plays a significant role in the performance and longevity of your pallet jack.

From choosing the right material and size to understanding the importance of regular maintenance and correct replacement techniques, these factors ensure your pallet jack operates efficiently.

Remember, each component requires careful consideration, whether it's pallet jack front wheels, load wheels, or specific pallet jack tires. By keeping these insights in mind, you can ensure that your pallet jack and its wheels remain in top condition, providing reliable service in your daily operations.

Frequently Asked Questions

What Are the Signs That I Need Pallet Jack Wheel Replacement?

You need pallet jack wheel replacement if you notice uneven wear, difficulty in maneuvering, or visible damage to the wheels, such as cracks or flat spots.

How Do I Choose the Right Pallet Jack Replacement Wheels?

When choosing pallet jack replacement wheels, consider the wheel material (like rubber or nylon), size matching your pallet jack, and the load capacity required for your operations.

Can I Replace the Electric Pallet Jack Wheels Myself?

Yes, you can replace electric pallet jack wheels with the right tools and knowledge. However, for complex models, professional assistance is recommended.

Are Pallet Jack Rubber Wheels Better Than Other Types?

Pallet jack rubber wheels are ideal for smooth, quiet operation, especially indoors, but other materials like nylon or steel might be better for heavier loads or specific floor types.

What's the Difference Between Pallet Jack Front Wheels and Load Wheels?

Pallet jack front wheels are mainly for steering, while load wheels, located at the back near the forks, are designed to support the weight of the load.

How Often Should I Check My Pallet Jack Tires and Wheels?

Regularly inspect your pallet jack tires and wheels, ideally every few months, to ensure they are in good condition and function safely and efficiently.

What Is the Process for Electric Pallet Jack Wheel Replacement?

Electric pallet jack wheel replacement involves identifying the correct wheel type, removing the old wheels, and installing new ones, ensuring they match the specifications of your electric pallet jack.

Our Products:

Contact Sourcefy:

Address:#108-209 Glen Cove Rd

Carle Place, NY

United States 11514

Email: support@sourcefy.com

Toll-free: 1-855-585-4430

Loading... Please wait...

Loading... Please wait...