- Home

- Forklift Parts

- Propane

- Carburetors

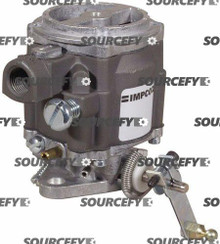

- CARBURETOR CA55-577 for Cascade

Forklift Parts Propane Carburetors CARBURETOR CA55-577

Category: Carburetors

Product Description

The CA55-577 Carburetors are an essential component tailored for Cascade equipment. They ensure optimal engine performance through precise fuel and air mixture management. Unlike typical carburetors, this carburetor is explicitly designed for the unique demands of industrial machines, providing reliable operation under various environmental conditions.

Its robust design helps maintain consistent engine temperature and efficiency, which is critical for the longevity and reliability of heavy-duty machinery. Knowledge about the mechanics of the CA55-577 can significantly enhance maintenance efficiency, as it simplifies adjustments and troubleshooting, which is critical for reducing downtime in industrial operations. Whether running a warehouse or a construction site, integrating this Carburetor for Cascade into your machinery lineup ensures smoother operations and enhanced engine response.

Features and Benefits:

-

Precision Mixing: Ensures optimal air-to-fuel ratio for efficient combustion.

-

Enhanced Durability: Built to withstand the rigorous demands of industrial environments.

-

Easy Maintenance: Simplified design allows for quick adjustments and repairs.

-

Energy Efficient: Reduces fuel consumption by maintaining consistent engine performance.

Symptoms of a Faulty CARBURETOR

A faulty carburetor can significantly disrupt engine performance and efficiency. Identifying early signs can prevent more severe issues and costly repairs.

-

Erratic Idling: The engine may idle too high or low, indicating inconsistent fuel and air mixture.

-

Poor Fuel Economy: Excessive fuel consumption might suggest the carburetor is not regulating the fuel mixture properly.

-

Engine Stalling: Difficulty in maintaining engine run, especially during idle or low-speed operations, points to carburetor issues.

-

Reduced Power: Noticeable engine power and acceleration loss, often due to improper fuel mixture.

-

Starting Issues: Challenges in starting the engine can often be traced back to carburetor malfunctions.

Frequently Asked Questions

What are the signs that I need to replace my carburetor?

Common indicators include:

-

Poor fuel efficiency.

-

Erratic idling.

-

Difficulty starting the engine.

-

Noticeable reductions in power.

If you experience these issues, inspecting or replacing the carburetor may be necessary to restore optimal engine performance.

How often should the carburetor be maintained for optimal performance?

Regular maintenance is crucial for longevity and efficiency. The carburetor should be checked annually or after every 1000 hours of operation. Cleaning and adjusting as needed can prevent common operational issues.

Can this carburetor be used in different types of industrial machines?

It is designed for versatility across various industrial applications, including forklifts, agricultural machinery, and construction equipment. Its robust design ensures reliable performance in diverse operational environments.

What improvements can I expect from installing a new carburetor?

Installing a new carburetor can improve fuel efficiency, smoother engine operation, better throttle response, and enhanced engine performance. These benefits contribute to extended machinery life and reduced operational costs.

Is there a specific type of fuel recommended for use with this carburetor?

While this carburetor is built to handle various fuel types, using clean, fresh gasoline or the specific fuel type recommended by your machine's manufacturer will ensure the best performance and prevent build-up within the fuel system.

Loading... Please wait...

Loading... Please wait...