- Home

- Forklift Parts

- Braking & Drive Axle

- Master Cylinders

Categories

Master Cylinders

Buy Brake Master Cylinders at Sourcefy - Order Today

Brake master cylinders are key to a forklift's safe stopping ability. They control the flow of brake fluid to the brakes, ensuring reliable stopping. Knowledge about how forklift brake master cylinders work is crucial for safe operation.

This guide covers their roles, maintenance, and common issues. It helps operators and maintenance teams keep forklifts running safely. Knowing about different aspects of brake master cylinders can prevent accidents and extend the forklift's life.

Function and Operation of Brake Master Cylinders

The brake master cylinder plays a crucial role in forklift operation and safety. It ensures that the force applied by the driver on the brake pedal effectively stops the vehicle.

-

Primary Function

The master cylinder effectively turns pedal force into hydraulic pressure. This pressure moves through the brake system to the wheels' brakes. It helps control and ensure reliable stopping of the forklift.

-

Dual-Circuit Design

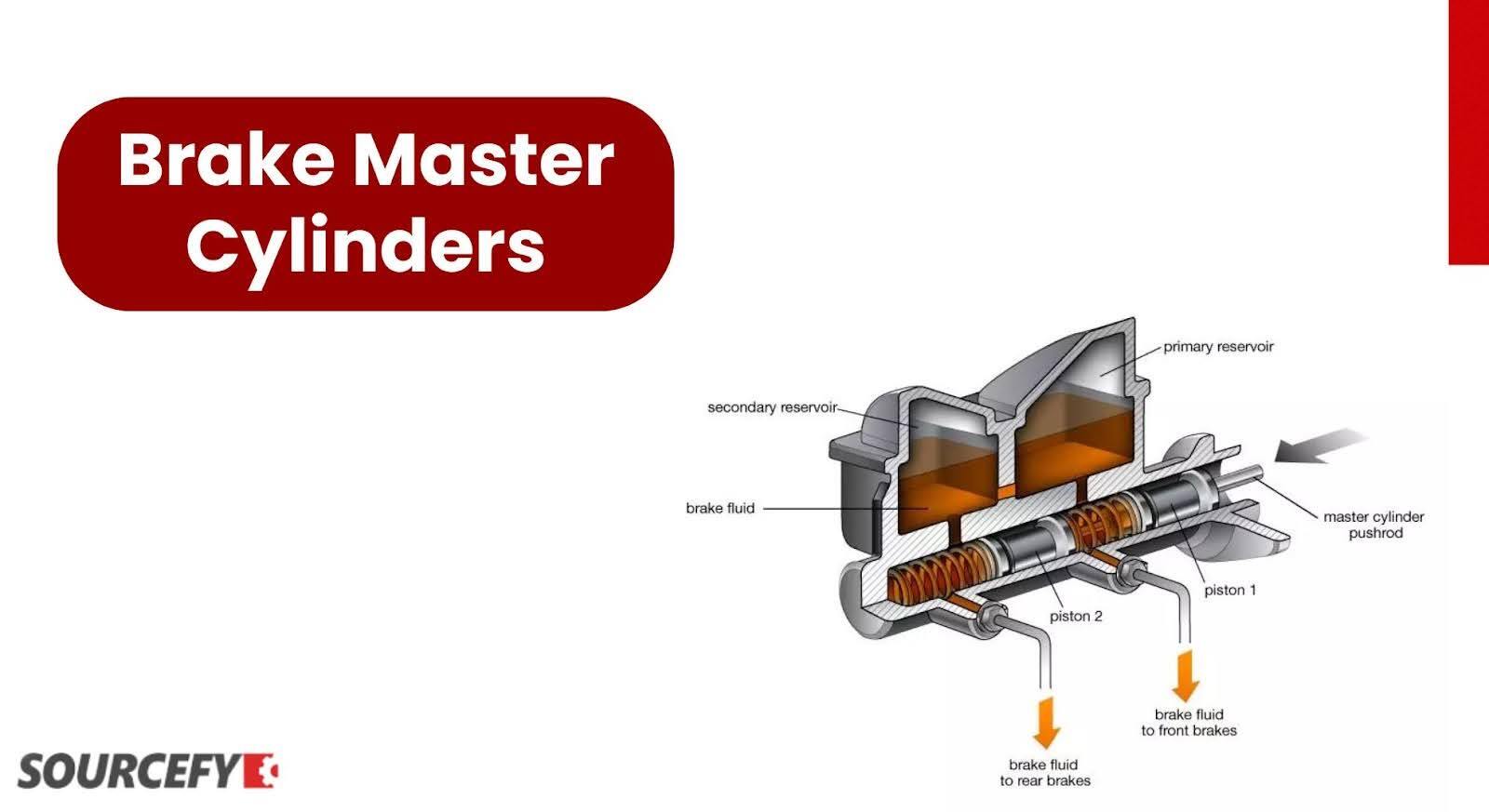

Many modern forklifts have a dual-circuit braking system, enhancing safety measures. In this system, the master cylinder has two pistons in separate chambers.

This dual-circuit design provides redundancy; if one circuit fails, like from a fluid leak, the other still works. This backup allows the forklift to stop even if part of the brake system fails, enhancing safety during operation.

Components of a Brake Master Cylinder

The brake master cylinder has several key components that work together to ensure effective braking. Each part is crucial for converting pedal force into hydraulic pressure to operate the vehicle's brakes.

- Reservoir: The reservoir, typically located on top of the cylinder, is the container for the brake fluid. It supplies the fluid necessary for the system to function and keeps it ready for when the brakes are activated.

- Piston(s): Pistons are critical components that move within the cylinder bore. Their movement creates the pressure needed to push the brake fluid through the system, activating the brakes.

- Seals: Seals play a vital role in maintaining the integrity of the braking system. They prevent brake fluid from leaking out and ensure the system remains airtight, which is crucial for proper brake function.

- Return Spring: The return spring is an essential component that returns the piston to its original position. This happens once the brake pedal is released. This action helps prepare the brake system for the next application, ensuring quick response times.

- Ports and Valves: These components manage the flow of brake fluid in and out of the brake lines. Ports and valves open and close at precise times during the braking process, allowing fluid to move where it is needed, ensuring efficient brake operation.

Types of Brake Master Cylinders

Brake master cylinders come in various types. Each type is designed to meet specific vehicle requirements and safety standards. Here's a detailed look at the common types of brake master cylinders used in different vehicles, including forklifts:

-

Single-Circuit

Single-circuit brake master cylinders operate all brakes with one piston. These are simpler and often found in older or budget vehicles. However, their major drawback is that a failure affects all the brakes simultaneously, posing a safety risk.

-

Dual-Circuit

Dual-circuit brake master cylinders have two chambers and pistons. They control the front and rear brakes independently. This design is standard in modern vehicles because it enhances safety. If one circuit fails, the other still works, allowing the vehicle to stop.

-

Tandem Brake Master Cylinders

Tandem brake master cylinders are a type of dual-circuit system with both pistons in one body. They provide the safety benefits of dual circuits but in a more compact unit. This design is popular in newer forklift and truck models for its efficient use of space and redundancy.

-

Load Sensing

Load-sensing brake master cylinders adjust brake pressure based on vehicle load. These are crucial for commercial vehicles and trucks that carry varying weights. They help maintain effective braking by changing pressure to match the load, improving both safety and brake wear.

-

Power-Assisted

Power-assisted brake master cylinders use a booster to help apply brake pressure. This booster is powered by the engine's vacuum or hydraulic pressure. These cylinders make braking easier and are especially useful in heavier vehicles. They reduce the physical effort needed to brake.

Maintenance and Longevity

Proper maintenance extends the life of brake master cylinders significantly. Regular care ensures they perform optimally throughout their service life.

- Check brake fluid levels regularly and top up if necessary. Use only the type of fluid specified for your forklift.

- Inspect for leaks around the master cylinder often. Leaks can lead to system failures.

- Change the brake fluid every two years to reduce wear and moisture inside the system.

Why Shop Forklift Brake Master Cylinders with Sourcefy?

Using reliable brake master cylinders is key to forklift safety. Sourcefy offers top-quality options to enhance your forklift's performance and safety.

- High-Quality Products: Sourcefy's brake master cylinders are durable and reliable, with a warranty. Trust us to provide the best quality at reasonable prices.

- Variety of Options: We have a wide range of brake master cylinders for all needs. Sourcefy ensures your forklift is safe and efficient from simple to advanced designs.

- Competitive Pricing: Sourcefy offers high-quality products at competitive prices. Save money while maintaining high safety standards.

- Exceptional Customer Service: Our team is here to help with any questions and provide expert advice. Sourcefy supports you from selection to installation, making your purchase easy.

Shop with Sourcefy to keep your forklift running safely and smoothly with the best brake master cylinders.

Frequently Asked Questions

Where Can I Find a Brake Master Cylinders Catalogue?

You can view our complete forklift parts catalogue on the Sourcefy website. It lists all models we offer with detailed specifications.

How Long Do Brake Master Cylinders Last?

Typically, brake master cylinders last between 5 to 10 years. Their lifespan depends on usage frequency and maintenance quality.

Why Do Brake Master Cylinders Fail?

Brake master cylinders fail due to wear and tear, fluid leaks, or corrosion. Improper maintenance can also lead to premature failure.

How Often Should I Inspect My Forklift's Brake Master Cylinder?

Inspect your forklift's brake master cylinder annually for signs of wear or leaks. Routine checks help prevent unexpected failures and maintain safety.

Loading... Please wait...

Loading... Please wait...