- Home

- Forklift Parts

- Braking & Drive Axle

- Wheel Cylinders

Categories

Wheel Cylinders

Buy Brake Wheel Cylinders at Sourcefy - Reliable Performance Guaranteed!

Brake wheel cylinders are key to the safety of any vehicle. They apply force to brake shoes, slowing the vehicle down safely. These components must be reliable to keep vehicles stopping correctly.

Quality brake wheel cylinders ensure every stop is smooth and safe. Reliable components reduce the risk of brake failure on the route. Choosing the right brake wheel cylinders is crucial for forklift safety. Trust Sourcefy in high-quality parts for peace of mind during every drive.

How Do Forklift Brake Wheel Cylinders Work?

Brake wheel cylinders are essential parts of drum brake systems. They use hydraulic pressure to activate the brakes. When you press the brake pedal, the fluid pushes the cylinder's pistons outward.

This action expands the brake shoes against the drum, slowing the forklift. As pressure is applied, the friction between the shoes and the drum stops the car. When you release the pedal, springs pull the shoes away from the drum, allowing the wheels to turn freely again. This cycle is crucial for controlled and effective braking.

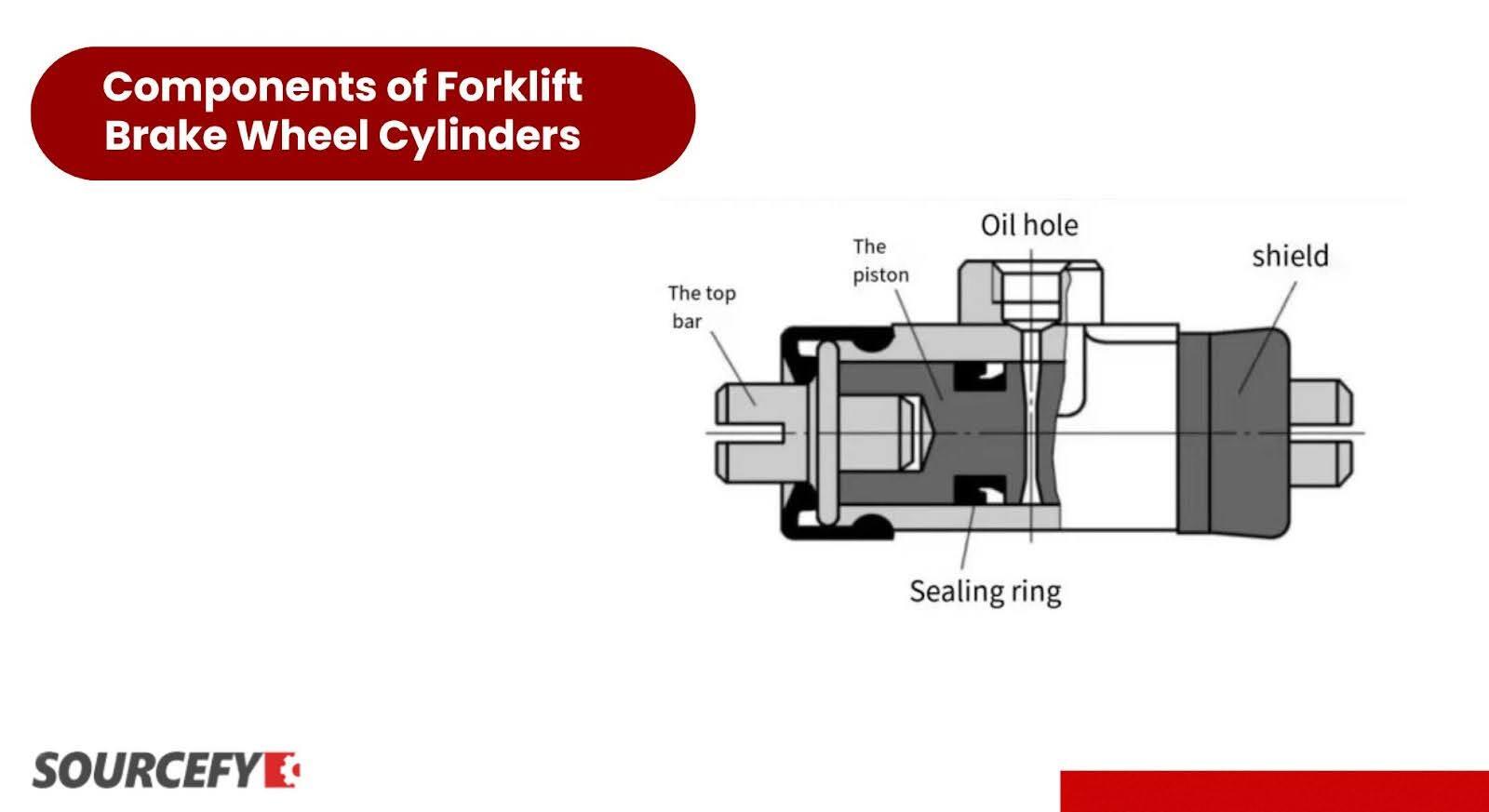

Components of Forklift Brake Wheel Cylinders

Brake wheel cylinders are relatively straightforward devices. They consist of several key components that allow effective function within a forklift's braking system. Here are the main components of a brake wheel cylinder:

- Cylinder Casing: This is the body of the wheel cylinder and is typically made of metal such as cast iron or aluminum. It houses all other components and is designed to withstand the hydraulic pressure exerted during braking.

- Pistons: These are located inside the cylinder casing and move outward when hydraulic pressure is applied. Most wheel cylinders have two pistons, one on each end, that push against the brake shoes.

- Rubber Seals: Each piston is equipped with rubber seals to prevent brake fluid from leaking out of the cylinder. These seals are crucial for maintaining the hydraulic pressure necessary for braking.

- Spring(s): A spring is often placed between the two pistons to keep them retracted when the brake pedal is not engaged. This prevents the brake shoes from rubbing against the drum when the vehicle is moving, reducing wear and tear.

- Bleeder Valve: This small valve is used for bleeding the brake system of air. Air in the brake lines can lead to a spongy brake pedal and reduced braking efficiency, so it is important to remove it.

- Dust Boots: These rubber covers protect the back ends of the pistons where they meet the cylinder casing. They prevent dirt, debris, and moisture from entering the cylinder and damaging the seals.

How to Install Forklift Brake Wheel Cylinders

These steps will help ensure a safe and effective installation of your forklift's brake wheel cylinders.

- Park the forklift and secure it to prevent any movement.

- Remove the wheel to access the brake drum and existing cylinder.

- Take off the brake drum to expose the wheel cylinder.

- Disconnect the brake line and remove the old wheel cylinder.

- Position the new brake wheel cylinder and secure it with bolts.

- Reconnect the brake line to the new cylinder.

- Replace the brake drum and mount the wheel back onto the forklift.

- Bleed the brake system to ensure there are no air bubbles.

- Test the brakes to make sure they function properly.

Tools and Precautions Needed for Installation

- Tools: Wrench set, screwdrivers, pliers, and a brake bleeder kit.

- Precautions: Always wear safety gloves and glasses to protect yourself. Ensure all tools are in good condition. Double-check all connections for leaks before completing the installation.

Maintaining Your Brake Wheel Cylinders

Following these maintenance tips can help extend the life of your brake wheel cylinders and ensure consistent braking performance.

- Regularly check brake fluid levels and top up if necessary.

- Inspect wheel cylinders for leaks or corrosion during routine maintenance.

- Clean around the cylinders to prevent dirt from causing damage.

Common Signs of Wear or Failure and How to Address Them

- If you notice brake fluid leaking, the cylinder may be failing.

- A soft brake pedal often indicates air in the hydraulic line.

- Replace worn cylinders to restore full braking power.

- Always bleed the brakes after installing new cylinders to remove air.

Why Buy Brake Wheel Cylinders From Sourcefy?

Choose Sourcefy for your brake wheel cylinders to enhance the safety and performance of your forklift, which is supported by our commitment to your satisfaction.

Trust in Quality and Reliability

At Sourcefy, we prioritize the quality and reliability of our brake wheel cylinders. Each product undergoes rigorous testing to meet the highest standards. This ensures that you receive parts that perform well and last long.

Wide Selection for All Needs

Sourcefy offers a diverse range of brake wheel cylinders suited for various types of forklifts and industrial vehicles. Whether you need a standard part or something more specific, we have options to fit your requirements.

Competitive Pricing and Value

We provide high-quality brake wheel cylinders at competitive prices. Investing in our products means you get excellent value without compromising on safety or performance.

Exceptional Customer Support

Our knowledgeable customer support team is here to assist you with any questions or needs you may have. From selecting the right product to guiding you through installation, we’re here to help every step of the way.

Frequently Asked Questions

What are Brake Wheel Cylinders?

Brake wheel cylinders are key parts of a drum brake system. They use hydraulic pressure to push brake shoes against the drum. This creates friction, helping the vehicle slow down or stop safely.

What Causes Wheel Cylinders to Leak?

Wheel cylinders can leak due to worn rubber seals or corrosion. Contaminated brake fluid can also damage seals, leading to leaks. Regular inspections can help catch leaks early and prevent brake failure.

How Long Do Wheel Cylinders Last?

Wheel cylinders can last several years with proper care and maintenance. Their lifespan depends on usage, brake fluid quality, and operating conditions. Periodic maintenance can extend their life and prevent issues.

How to Replace Wheel Cylinders?

To replace forklift wheel cylinders, secure the vehicle and remove the drum. Disconnect the brake line and mounting bolts, then install a new cylinder. Always bleed the brakes after replacement to ensure proper functioning.

Why are Forklift Wheel Cylinders Important?

Forklift wheel cylinders ensure safe braking by controlling brake shoe movement. They help forklifts handle heavy loads and operate safely in various conditions. Keeping them in good condition is vital for safe operations

Loading... Please wait...

Loading... Please wait...