- Home

- Forklift Parts

- Horns - Horn Accessories

Categories

Horns - Horn Accessories

In the bustling environment of industrial operations, the modest forklift horn plays a key role in ensuring safety and efficient communication. Adhering to OSHA forklift horn regulations, each beep of the horn serves as a critical alert amidst the daily hum of activity. From the distinctive forklift horn sound that cuts through the noise to the tactile feedback of a forklift horn button, these components are essential in various models, including Toyota, Nissan, and Hyster forklifts.

Beyond mere noise, forklift horns symbolize a commitment to safety, reminding operators and pedestrians alike of the importance of attention in industrial settings. This integral tool, often overlooked, is a cornerstone in forklift horn safety, ensuring a harmonious and secure workflow.

Exploring Forklift Horns

Forklift horns are essential for safety in places like warehouses and construction sites. The sound helps keep everyone safe by warning people that a forklift is nearby. Different brands of forklifts, like Toyota, Nissan, and Hyster, have horns with unique sounds.

For example, a Toyota forklift horn might have a different beep compared to a Nissan forklift horn. The sound of each horn is designed to be clear and loud enough to be heard over other noises in busy work areas. This way, no matter what forklift is being used, the horn helps avoid accidents and keep everyone aware of the forklift's movements.

Importance of Horns in Forklift Safety

Forklift horns play a vital role in ensuring workplace safety. Their primary function is to alert people in the surroundings of the forklift's movements, especially in areas where visibility might be limited, like corners or near doors. A loud and clear horn, such as those found on Toyota, Nissan, or Hyster forklifts, can effectively warn nearby workers and prevent accidents.

Here's how the importance of horns in forklift safety, along with OSHA regulations, can be presented in a clear and structured manner:

- Horn Usage for Safety Alerts: Forklift horns are critical for alerting nearby workers, particularly in areas with limited visibility. Using the horn can prevent collisions and accidents.

- OSHA Regulations on Daily Inspections: According to OSHA standard 29 CFR 1910.178(q)(7), industrial trucks, including forklifts, must be inspected daily. This ensures all safety features, like the horn, are in working condition.

- Requirement for Functional Horns: As per OSHA's 1910.178(p)(1), if a forklift is found to be defective or unsafe (e.g., a non-functional horn, etc), it should not be used until it is repaired and deemed safe.

- Horn Sound Level: A forklift's horn must be loud enough to be heard above the ambient noise in the workplace. If the horn's sound level deteriorates, the forklift is considered unsafe.

- Maintenance of Horn and Parts: OSHA's 1910.178(q)(5) states that any parts requiring replacement, including those of the horn, must be as safe as those in the original design.

- Practical Tips for Horn Usage:

- Regularly test the horn to ensure it's loud and clear.

- Always keep the forklift horn button within easy reach for quick use.

- Use the horn at critical times, like when approaching blind spots or backing up.

- Ensuring Compliance: Regular maintenance and adherence to OSHA's safety standards are essential to keep the forklift and its horn in optimal condition for safe operation.

Horn Accessories and Their Functions

Forklift horns come with different accessories that make them work better and keep everyone safer. Let's look at some of these accessories and how they help:

Forklift Horn Button

This is the most important part. It's usually located where the driver can easily reach it. When the driver presses the button, the horn makes a loud sound. It's simple to use and helps drivers quickly warn others, especially in busy areas.

Sound Amplifiers

Some forklifts, like the Toyota, Nissan, and Hyster models, can have sound amplifiers. These make the horns sound louder, so they're heard over other noises in places like big warehouses.

Horn Covers

These protect the horn from dust and damage. A well-protected horn is more likely to work well when it's needed.

Adjustable Volume Control

This lets the forklift driver change how loud the horn is. In quieter places, the horn can be softer. It can be turned up in louder areas so it's heard clearly.

Different Sound Options

Some horns can make different sounds. This can be useful in places where different beeps mean different things. It helps everyone understand what the forklift is doing, like moving forward or backing up.

All these accessories help make the forklift horn a better tool for safety. They ensure the horn's sound is just right wherever the forklift is working.

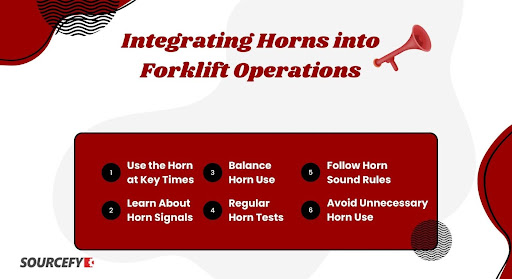

Integrating Horns into Forklift Operations

Using the horn right is a big part of driving a forklift safely. Here are some tips on how to do it:

- Use the Horn at Key Times: Like when coming to corners or busy spots. This lets others know you're there.

- Balance Horn Use with Other Safety Steps: Don't rely on the horn. Always look around and drive carefully.

- Follow the Horn Sound Rules: Make sure your forklift's horn, whether it's a Toyota, Nissan, or Hyster, can be heard well.

- Learn About Horn Signals: Everyone should know what different horn sounds mean.

- Regular Horn Tests: Check the forklift horn and its button often to make sure they work.

- Avoid Unnecessary Horn Use: Only use the horn when needed to avoid confusion.

By using the horn smartly and following these tips, forklift drivers can help keep their workplace safe.

Conclusion

The forklift horn is much more than just a sound-making device; it's a key element in ensuring workplace safety. Adhering to OSHA forklift horn regulations, understanding the unique horn sounds of different models like Toyota, Nissan, and Hyster, and proper usage of the forklift horn button are all crucial. Regular maintenance and an awareness of forklift horn safety standards play significant roles in preventing accidents.

By integrating these practices into daily operations, forklift operators can create a safer, more efficient work environment. Remember, every beep of the forklift horn is a step towards maintaining a secure and accident-free workplace. Let's continue to prioritize safety and utilize these tools effectively for the well-being of all.

Frequently Asked Questions

How Often Should I Check My Forklift Horn?

As per OSHA regulations, check your forklift horn daily to ensure it's loud and clear.

What Makes the Sound of Toyota, Nissan, and Hyster Forklift Horns Different?

Like Toyota, Nissan, and Hyster, each brand designs its forklift horns with unique sound characteristics for distinct audibility.

Is It Mandatory to Have a Horn on Every Forklift?

Yes, OSHA regulations require a functional horn on all forklifts for workplace safety.

How Do I Know If My Forklift Horn Is Loud Enough?

The horn should be audible over ambient workplace noise, ensuring effective communication and safety.

What Should I Do If My Forklift Horn Button Is Not Working?

If the horn button is unresponsive, inspect the wiring and connections and repair or replace as needed.

Can The Sound of a Forklift Horn Be Adjusted?

Some forklifts allow sound adjustment. Always ensure it meets safety standards for clarity and volume.

Are There Specific Times When Using the Forklift Horn Is More Important?

Use the horn, especially at blind spots and intersections and while reversing to alert others.

Loading... Please wait...

Loading... Please wait...