- Home

- Pallet Jack Parts

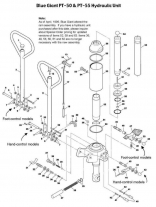

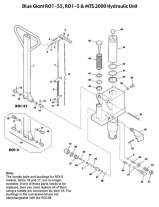

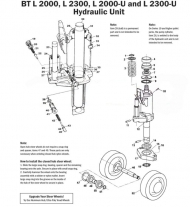

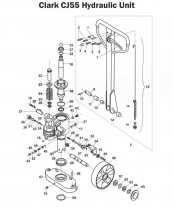

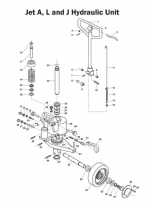

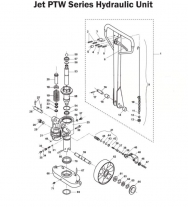

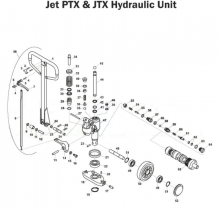

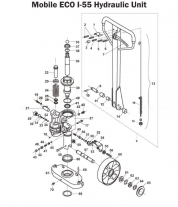

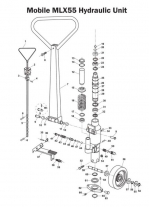

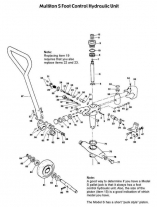

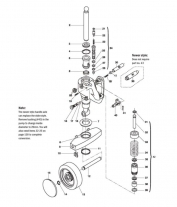

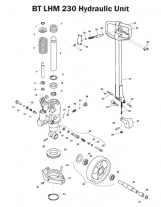

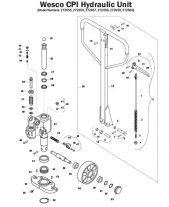

- Manual Pallet Jack Hydraulic Parts

Categories

Manual Pallet Jack Hydraulic Parts

Manual Pallet Jack Hydraulic Parts (Sub Category Page)

Manual pallet jacks are essential tools in industrial settings, helping workers easily move heavy loads. These devices are used in warehouses, factories, and distribution centers. The hydraulic system in hydraulic pallet jacks makes lifting and transporting pallets possible.

This blog post will focus on the crucial hydraulic parts of manual pallet jacks, including the pallet jack hydraulic pump and other key components. Knowing about these parts is important for maintaining and optimizing the performance of your equipment.

Proper knowledge ensures smooth operation, reduces downtime, and extends the lifespan of your pallet jacks, enhancing workplace productivity and safety.

What is a Manual Pallet Jack?

A manual pallet jack is a hand-powered tool used to lift and move pallets. It is commonly found in warehouses, factories, and retail stores. This simple yet effective device allows workers to transport heavy loads over short distances without needing a forklift. The primary uses include moving palletized goods, arranging stock in storage areas, and loading or unloading trucks.

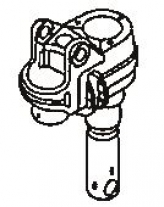

The basic structure of a manual pallet jack includes:

- Two forks that slide under a pallet.

- A hydraulic pump that lifts the forks.

- A handle for steering and operating the pump.

Key components also include the hydraulic cylinder, wheels for movement, and control levers for lifting and lowering the load. These parts make the manual pallet jack an essential tool for efficient material handling.

Key Hydraulic Parts of a Manual Pallet Jack

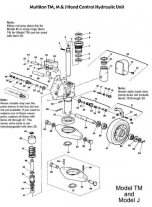

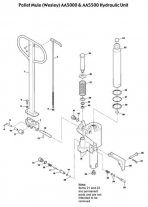

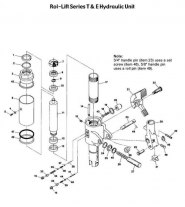

A manual pallet jack, also known as a pallet truck, is a tool used to lift and move pallets. It has various hydraulic parts that enable it to function efficiently. Here are the main hydraulic components:

- Hydraulic Pump: This basic component creates the pressure to lift the pallet. It operates by drawing hydraulic fluid from the reservoir and pressurizing it. The pallet jack hydraulic pump is essential for lifting, as it provides the necessary force to raise heavy loads with minimal effort.

- Hydraulic Cylinder: The cylinder converts hydraulic energy into mechanical energy. When pressurized fluid enters the cylinder, it pushes the piston, which lifts the forks of the pallet jack. This part is crucial in hydraulic pallet jacks for smooth lifting, ensuring that the forks can raise and lower loads efficiently and safely.

- Hydraulic Reservoir: This tank holds the hydraulic fluid required for the system to function. The fluid needs to be checked and maintained regularly to ensure smooth operation. The pallet jack hydraulic parts cannot work efficiently without a properly maintained reservoir. Keeping the reservoir clean and filled with the correct fluid is vital for the pallet jack's overall performance.

- Hydraulic Fluid: This specialized oil transfers pressure within the hydraulic system. The pallet jack needs to be clean and at the correct level to operate efficiently. Proper hydraulic fluid ensures the smooth operation of hydraulic pallet jacks by reducing friction and wear on internal components, thus extending the lifespan of the equipment.

- Control Valve: The control valve regulates the flow of hydraulic fluid to the cylinder. It allows the operator to control the lifting and lowering of the pallet jack. This part is important for the precise movement of the pallet jack, enabling the operator to handle loads with accuracy and ease. The control valve ensures that the hydraulic system responds correctly to user inputs, making load handling safe and efficient.

- Seals and O-rings: These are essential for preventing leaks in the hydraulic system. They ensure that the hydraulic fluid remains contained within the system, maintaining pressure and efficiency. Good seals and O-rings are key to the effective functioning of pallet jack hydraulic parts, as they prevent the loss of hydraulic fluid, which can lead to a drop in lifting performance and potential damage to the system.

- Lift Chain: Although not hydraulic, the lift chain works in conjunction with the hydraulic cylinder to raise and lower the forks. It helps in the smooth operation of lifting and lowering pallets, providing additional support and stability to the hydraulic system. The lift chain ensures that the forks move uniformly and can handle the weight of the load without bending or breaking.

Supporting Parts and Their Roles

The supporting parts of a manual pallet jack are crucial for its overall functionality and efficiency. Each component plays a specific role in ensuring smooth operation and safe handling of heavy loads.

- Handle and Control Lever: The handle steers the pallet jack, while the control lever operates the hydraulic system. Pumping the lever activates the hydraulic pump to lift the forks, with positions for lifting, lowering, and neutral for precise control.

- Forks: Made from high-strength steel, the forks slide under a pallet to lift it. They are designed to handle heavy loads, ensuring the pallet can be moved easily and safely.

- Wheels and Rollers: The front wheels steer the pallet jack, while the load rollers support the load at the fork ends. These parts ensure smooth movement and maneuverability, even in tight spaces.

- Chassis: The main frame supports all components and bears the load during operations. Made from robust materials, it provides stability and structural integrity.

- Load Rollers Brackets and Bearings: Brackets hold the load rollers, while bearings reduce friction at pivot points. Together, they ensure smooth operation and efficient movement of the pallet jack.

Maintenance Tips for Hydraulic Pallet Jacks

Regular maintenance ensures the longevity and efficiency of your hydraulic pallet jack. Here are some essential tips to keep your equipment in top condition:

- Inspect hydraulic fluid levels weekly to ensure proper operation and avoid damage.

- Check for hydraulic fluid leaks regularly to maintain system pressure and efficiency.

- Lubricate moving parts frequently to reduce friction and prevent wear and tear.

- Examine seals and O-rings for damage, replacing them to prevent hydraulic leaks.

- Clean the hydraulic reservoir to remove contaminants and ensure fluid purity.

- Test the control valve and handle for smooth operation and accurate response.

- Inspect wheels and rollers for damage, ensuring smooth movement and maneuverability.

Conclusion

Understanding the hydraulic parts of manual pallet jacks is crucial for maintaining their efficiency and longevity. The hydraulic system, including the pallet jack hydraulic pump and various other components, plays a critical role in the lifting and moving of heavy loads.

Routine maintenance, such as checking hydraulic fluid levels, inspecting for leaks, and lubricating moving parts, ensures that hydraulic pallet jacks operate smoothly and safely.

Keeping these parts in good condition can reduce downtime and enhance productivity in your industrial setting. Proper care of your pallet jack hydraulic parts extends your equipment's life and ensures a safer and more efficient working environment.

Frequently Asked Questions

What Are Hydraulic Pallet Jacks?

Hydraulic pallet jacks are manual tools used to lift and move pallets. They rely on a hydraulic system to provide the necessary lifting power, making it easier to handle heavy loads in warehouses and other industrial settings.

How Does a Pallet Jack Hydraulic Pump Work?

A pallet jack hydraulic pump operates by drawing hydraulic fluid from a reservoir and pressurizing it. This pressurized fluid then moves a piston within the hydraulic cylinder, lifting the forks and allowing the pallet jack to raise heavy loads efficiently.

What Are The Main Hydraulic Parts of a Pallet Jack?

The main hydraulic parts of a pallet jack include the hydraulic pump, hydraulic cylinder, reservoir, control valve, seals, and O-rings. These components lift and lower loads smoothly, ensuring the pallet jack operates effectively.

Why Is Maintenance Important for Hydraulic Pallet Jacks?

Hydraulic pallet jacks require maintenance to ensure smooth and safe operation. Frequent checks on hydraulic fluid levels, inspections for leaks, and lubrication of moving parts help extend the pallet jack's lifespan and prevent costly repairs.

How Often Should I Check The Hydraulic Fluid in My Pallet Jack?

Hydraulic fluid in your pallet jack should be checked weekly to ensure proper levels and cleanliness. Maintaining the correct fluid level and quality helps the hydraulic system function efficiently, preventing damage and ensuring smooth operation.

Loading... Please wait...

Loading... Please wait...