- Home

- Forklift Parts

- Braking & Drive Axle

- Master Cylinders

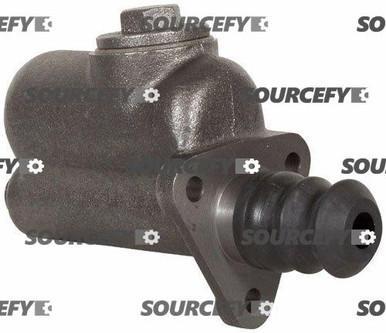

- MASTER CYLINDER FE-1476

Forklift Parts MASTER CYLINDER FE-1476

Category: Master Cylinders

Product Description

The Master Cylinder FE-1476, a key component in brake systems, transforms pedal pressure into hydraulic power. This brake master cylinder ensures your machine stops effectively, safeguarding operator safety. Installation is user-friendly: securely mount it, connect brake lines, and bleed the system to remove air.

Regular checks for leaks or wear are vital for maintenance. If you notice decreased braking efficiency or fluid leakage, it's time to replace it. A new cylinder restores optimal brake function, ensuring your industrial machine operates safely and efficiently. Understanding and maintaining the cylinder is essential for smooth, secure machine operation.

Product Specifications

|

Part Type |

Master Cylinder |

|

Cylinder Length |

6.34” / 161mm |

|

Mounting Hole Distance |

2.36” / 60mm |

|

Bore Size |

1” |

|

Oil Type |

Brake |

|

Includes Push Rod |

No |

|

Repair Kit |

SY52063 |

|

Cross References |

800051730, 3042212, 3002619, 220000936, 005915218881, 005913135981, 005911099681, YT220000936, WGF2775, TY00591-52188-81, TY00591-31359-81, TY00591-10996-81, SY52050, NICK899499, MB971067, MB0971067, LP605-1431, INME-1002, INFE1476AX, INFE1476-1X, INFE-1476A, INE-1476A, HY3002619, GM0246-5562, ET151481, ET15127, CT971067, CT0971067, CL899499, CL3761960, CL1310707 |

Features

Discover the robust design of the Master Cylinder FE-1476 for enhanced braking efficiency in industrial machinery.

- Precision Hydraulic Conversion: Converts pedal force into hydraulic pressure with high accuracy for responsive braking.

- Durable, Corrosion-Resistant Construction: Built from corrosion-resistant materials to withstand harsh conditions and reduce maintenance.

- Compatible Design for Versatile Use: Fits seamlessly with multiple machine models, enhancing its adaptability across applications.

- Efficient Bore Size for Consistent Pressure: The 1-inch bore provides steady hydraulic flow, maintaining reliable braking power.

Benefits:

Using the Master Cylinder FE-1476 provides a reliable solution for safe and efficient machine operation.

- Enhanced Operator Safety: Consistent braking response improves control in high-risk environments.

- Reduced Downtime with Easy Maintenance: Minimal upkeep needs ensure consistent performance without frequent repairs.

- Cost-Effective and Long-Lasting: Durable design reduces replacement frequency, saving costs over time.

- Boosted Machine Performance: Reliable braking function elevates machine reliability in demanding tasks and resistant to corrosion and wear, extending its lifespan.

Recommended Use/Applications

Ideal applications for the master cylinder in heavy-duty industrial settings.

- Construction Equipment: Maintains reliable stopping power in rugged, heavy-use environments.

- Agricultural Machinery: Handles frequent start-stop cycles for fieldwork.

- Mining Vehicles: Performs under high-pressure conditions in mining applications.

- Material Handling Machines: Essential for safe operation in distribution centers.

- Forklifts: Ensures dependable braking in fast-paced logistics hubs.

Frequently Asked Questions

How does a brake master cylinder function?

It converts pedal pressure into hydraulic power, enabling effective braking in machines.

What is the installation process for a master cylinder?

Mount it securely, connect the brake lines, and bleed the system to remove trapped air.

Is it compatible with different machine models?

Yes, its versatile design ensures compatibility with various industrial machines.

What are the signs that a master cylinder needs replacement?

Reduced braking efficiency and fluid leakage are critical indicators for replacement.

How often should it be maintained?

Regular checks for wear and leaks are recommended to ensure optimal function and safety.

Can the master cylinder be repaired, or should it be replaced?

While minor issues can be repaired, significant wear or damage often necessitates replacement.

Loading... Please wait...

Loading... Please wait...