- Home

- Pallet Jack Parts

- Manual Pallet Jack Hydraulic Parts

- MIGHTY LIFT ML55 HYDRAULIC UNIT

- Mighty Lift Lever Plate ML B135

- Home

- Search By Make

- Pallet Jack Parts

- MIGHTY

- Manual Pallet Jack Hydraulic Parts

- LIFT ML55 HYDRAULIC UNIT

- Mighty Lift Lever Plate ML B135

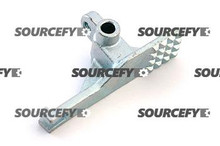

Pallet Jack Parts Manual Pallet Jack Hydraulic Parts MIGHTY LIFT ML55 HYDRAULIC UNIT Lever Plate ML B135

Category: LIFT ML55 HYDRAULIC UNIT

Product Description

The Mighty Lift Lever Plate MLB135 is a critical component in material handling equipment by Mighty Lift. Designed for durability and efficiency, the lever plate MLB135 plays a crucial role in the functionality of pallet jacks and similar devices.

It aids in the precise control and maneuverability of the load, ensuring smooth operation during lifting and moving tasks. The lever plate for Mighty Lift is engineered to withstand heavy use in industrial environments, making it an essential upgrade or replacement part that enhances the longevity and performance of your machinery. Knowing about its installation and maintenance can significantly impact operational efficiency, reducing downtime and increasing productivity in any industrial setting.

Mighty Lift Lever Plate ML B135

Product Specifications

|

Part Type |

Lever Plate |

|

Model Number |

ML B135 |

|

Make |

Mighty Lift |

|

Condition |

Brand New |

|

Fitment Type |

Direct Replacement |

Features

Explore the technical innovations of the Mighty Lift Lever Plate MLB135 that enhance its performance in industrial applications:

-

Material Composition: Crafted from high-grade steel, ensuring maximum durability and resistance to wear under rigorous use.

-

Design Precision: Engineered with exacting tolerances to ensure a perfect fit and functionality within Mighty Lift equipment.

-

Corrosion Resistance: Features a protective coating that prevents rust and corrosion, extending the lifespan of the lever plate even in harsh environments.

-

Load Handling: Optimized for handling varying weight capacities without deformation, maintaining structural integrity under stress.

Benefits

The MLB135 lever plate offers distinct advantages to streamline operations and enhance safety in industrial settings:

-

Enhanced Efficiency: Facilitates smoother lifting and moving operations, reducing effort and increasing throughput.

-

Reliability: With its robust construction, it consistently performs well, minimizing the likelihood of equipment failure.

-

Ease of Maintenance: Its design simplifies routine checks and replacements, ensuring equipment remains operational with minimal downtime.

-

Safety Enhancement: Improves overall equipment stability and control, contributing to a safer workplace by reducing accident risks.

Symptoms of a Faulty Lift Lever Plate

Recognizing the signs of a faulty lift lever plate is crucial for maintaining operational safety and efficiency. Here are common indicators that suggest issues:

-

Increased Friction: Noticeable resistance when lifting or moving, indicating wear or misalignment of the lever plate.

-

Unusual Noises: Sounds such as grinding or clicking during operation may signal a deteriorating lever plate.

-

Reduced Responsiveness: The lever requires more effort or multiple attempts to engage or operate effectively.

-

Visible Wear: Signs of excessive wear or damage on the plate surface, such as scratches or bending.

-

Operational Inconsistency: The lift mechanism behaves erratically, performing differently under the same conditions.

Recommended Use/Applications

-

Warehouse: Ideal for managing loads in high-volume storage facilities.

-

Logistics: Enhances efficiency in retail stock handling and management.

-

Manufacturing: Perfect for consistent use in assembly or production lines.

-

Construction: Supports material movement on dynamic construction grounds.

Frequently Asked Questions

What are the key specifications to consider before buying a lever plate?

When selecting a lever plate, consider its material compatibility, load capacity, and dimensional accuracy to ensure it fits your existing equipment and meets operational demands. The corrosion resistance feature is crucial for longevity, especially in harsh environments.

How do I determine if a lever plate is compatible with my equipment?

Check the part number and dimensions against your equipment manufacturer's specifications. A compatible lever plate should match the original part's size, fit, and function to ensure seamless integration and operation.

What maintenance is required for a lever plate to ensure long service life?

Regular inspections for signs of wear, such as cracks or deformations, are crucial. Applying lubricants can prevent rust and reduce friction, extending the lifespan of the lever plate. Always replace the plate if you notice any severe damage or wear.

Can a lever plate improve the efficiency of my machinery?

Yes, a well-designed lever plate can significantly enhance the efficiency of your machinery by ensuring smoother and more reliable operations. This improvement is particularly noticeable in high-demand environments where precision and durability are critical.

What safety precautions should I follow when replacing a lever plate?

Always ensure the machinery is switched off and stabilized. Use appropriate tools and follow the manufacturer's guidelines to avoid misalignment, which could lead to operational hazards. Regular training on equipment maintenance for operational staff is also recommended.

How often should a lever plate be replaced in industrial machinery?

The replacement frequency depends on usage intensity and environmental conditions. Regularly scheduled maintenance checks can help you monitor its condition and perform replacements when necessary to prevent machinery downtime.

Loading... Please wait...

Loading... Please wait...