- Home

- Sweepers and Scrubbers

- Actuators

Categories

Actuators

Categories

Actuators

Actuators are a keystone in industrial machinery, particularly in sweepers and scrubbers. They range from the robust Clark actuator to the precision-driven American Lincoln and Advance actuators, which are essential for the smooth operation of these machines.

In this guide, we will look into what an actuator is and its pivotal roles, exploring various types, including power actuators. Whether you're a professional in the industry or simply curious, this page will show actuators' significance and diverse functions in modern industrial equipment.

What is an Actuator?

An actuator is a machine component that moves or controls a mechanism or system. It converts energy, often electrical, hydraulic, or pneumatic power, into mechanical motion. This motion can be linear, as in a cylinder moving back and forth, or rotary, as in a rotating motor.

The primary function of an actuator is to apply force and control motion within machinery and equipment. It is a crucial part of any mechanized system and can be found in various applications, from industrial machinery to consumer electronics.

Role in Sweepers and Scrubbers

In sweepers and scrubbers, actuators are the driving force behind crucial functions. They manage movements such as the rotation of brushes, extension of arms, or the adjustment of cleaning heads.

This ensures the machines can effectively navigate and clean different surfaces and areas, adapting to various cleaning challenges.

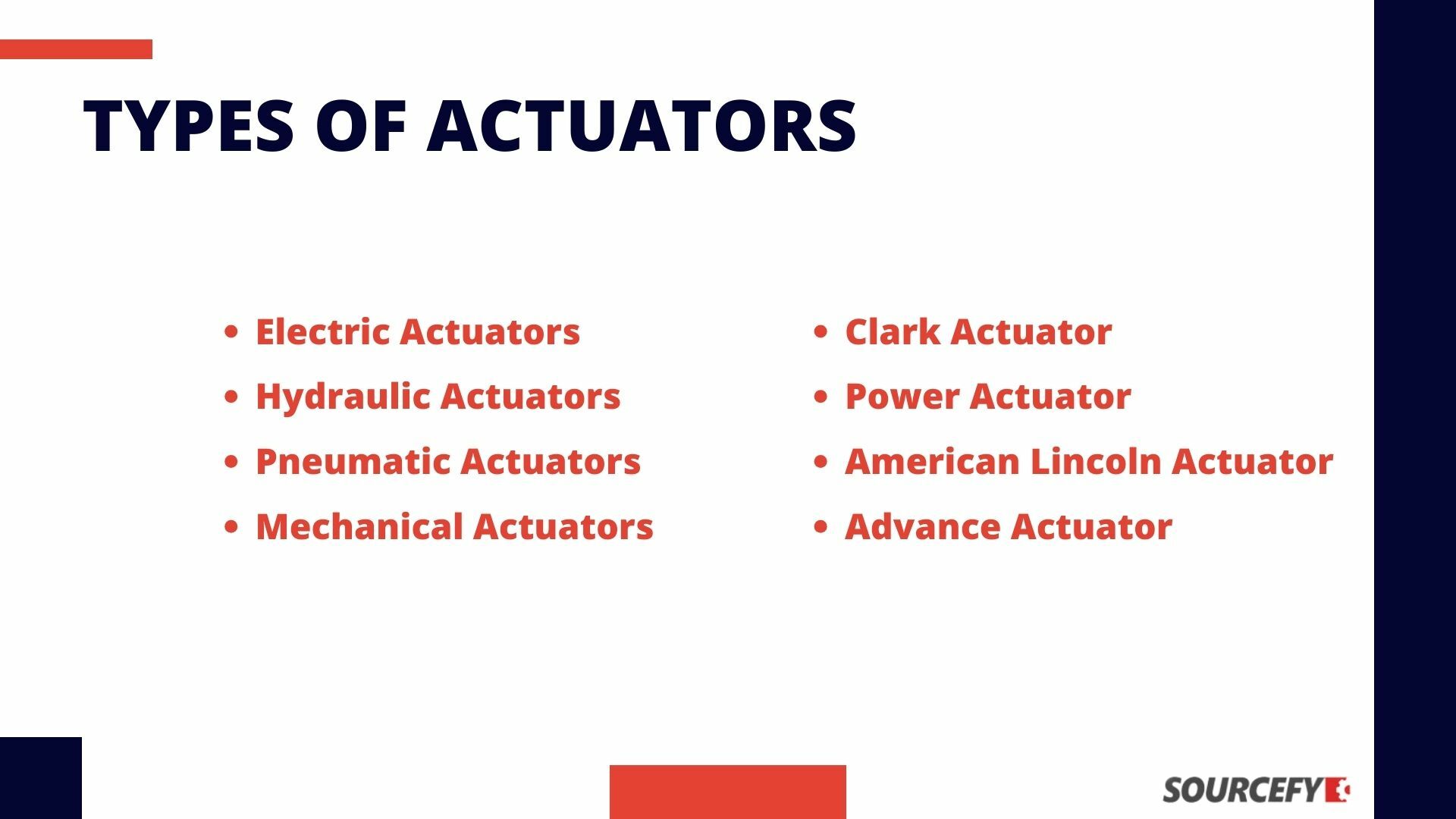

Types of Actuators

Actuators come in various forms, each with unique strengths and specialized functions. Understanding these categories helps select the proper actuator for specific industrial tasks, whether for precise control or robust power.

Electric Actuators

These use electric motors to create motion. They are often preferred for precise control and are widely used in robotics, automation, and consumer electronics.

Hydraulic Actuators

These use fluid pressure to create motion and are known for their ability to exert large forces. They are commonly used in heavy machinery like construction equipment and aircraft systems.

Pneumatic Actuators

These use compressed air to create motion and are often used for applications requiring quick, repetitive motion, such as factory automation.

Mechanical Actuators

These convert rotary motion into linear motion and vice versa, often using gears, screws, or similar mechanisms. They are commonly found in manual applications like valve handles or jacks.

Clark Actuator

The Clark actuator is a powerhouse known for its strength and dependability. It's the go-to component in machines tasked with heavy-duty work. Its robust design ensures reliability even under tough conditions, making it a popular choice in industrial applications.

Whether lifting heavy loads or operating under challenging environments, the Clark actuator is engineered to handle it all easily.

Power Actuator

Power actuators are all about delivering high-strength performance. These actuators are designed to provide the force for machines requiring intense power. They are essential in applications where strength is not just an advantage but a requirement.

Power actuators are the muscle behind some of the most demanding tasks, from pushing heavy materials to powering large mechanical arms.

American Lincoln Actuator

Precision and top-notch quality define the American Lincoln actuator. It's preferred in machines where precise control and accurate movements are critical. This actuator stands out for its ability to perform complex tasks precisely.

It's beneficial in applications where even the slightest deviation can have significant impacts, ensuring operations are carried out accurately.

Advance Actuator

Known for its cutting-edge technology and adaptability, the Advance actuator is a versatile component suitable for various machinery. Its advanced design allows for seamless integration into various systems, making it a preferred choice for diverse applications.

The advanced actuator excels in adapting to tasks requiring delicate handling or robust action, ensuring optimal performance across various machines.

Maintenance of Actuators

Effective maintenance of actuators is crucial for the longevity and reliability of machinery.

- Regularly inspect for wear and tear.

- Check and secure electrical connections.

- Lubricate moving parts routinely.

- Listen for unusual operational noises.

- Monitor for decreased movement efficiency.

- Look for visible wear or damage.

- Replace actuators promptly when needed.

Conclusion

In industrial machinery, the actuator is a crucial component, integral to the functionality and efficiency of devices like sweepers and scrubbers. It is essential for anyone involved in this field to understand what an actuator is and its various types, from the robust Clark actuator to the precision-driven American Lincoln and versatile Advance actuator.

These components, whether a power actuator delivering formidable force or a specialized actuator for specific needs, play a vital role in the smooth operation of machines. Proper maintenance and timely replacement of these actuators ensure that machinery continues to operate at its best, highlighting the undeniable importance of actuators in the industrial world.

Frequently Asked Questions

What Is an Actuator in Industrial Machines?

An actuator in industrial machines is a component that helps in creating movement. It converts energy into mechanical motion, which is pivotal in controlling various machine parts.

When Should a Clark Actuator Be Replaced?

A Clark actuator should be replaced when it shows signs of wear, reduced efficiency, or irregular performance. Regular inspections can help identify these issues early.

What Makes a Power Actuator Different?

A power actuator is designed for strength and high-force applications. It is ideal for machinery requiring substantial power to operate efficiently.

Why Choose an American Lincoln Actuator for Industrial Use?

An American Lincoln actuator is known for its precision and reliability, making it suitable for applications where exact movements are crucial.

How Does an Advanced Actuator Enhance Machine Performance?

An advanced actuator offers advanced technological features and versatility, making it a great choice for diverse industrial applications requiring adaptable and efficient performance.

Can Actuators from Different Brands Be Interchanged in Machinery?

While some actuators might be interchangeable, it's essential to check compatibility. Factors like size, power requirements, and control systems must align with the specific needs of the machinery.

Loading... Please wait...

Loading... Please wait...