- Home

- Forklift Parts

- Water Pumps

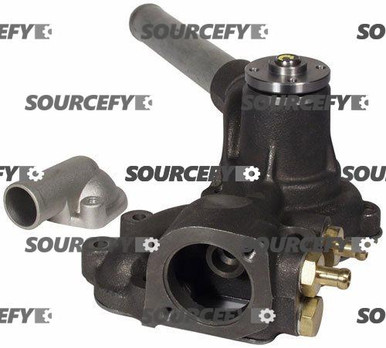

- WATER PUMP 1376005 for Hyster

Water Pump 1376005 for Hyster

Category: Water Pumps

Product Description

The 1376005 water pump is an essential component designed to maintain the optimal temperature of engines, particularly in Hyster forklifts. It ensures the coolant circulates appropriately, preventing the engine from overheating during heavy-duty operations. Overheating can reduce engine efficiency and lifespan, so keeping the water pump in good working order is vital. A common misconception is that all water pumps function the same way, but the water pump 1376005 for Hyster and similar models are built to handle the specific cooling needs of heavy machinery.

Made from highly durable materials, this pump can withstand intense industrial environments, reducing the need for frequent replacements. Regular maintenance is crucial to avoid potential engine failures, especially in machines that run for long periods under heavy loads. Understanding how this pump contributes to the overall performance of forklifts can help improve efficiency and reduce costly downtime.

|

Cross Reference |

HYSTER1376005 1376005 HYSTER 1376005 , HY1376005 |

Water Pump 1376005 for Hyster

Product Specifications

|

Part Type |

Water Pump |

|

Model Number |

1376005 |

|

Make |

Hyster |

|

Condition |

New |

|

Compatible Equipment Type |

Forklifts |

|

Fits to |

VA Engines |

|

Height |

4.55" 116MM |

|

Length |

17.32" 440MM |

|

Mounting Holes |

4 |

Features

The 1376005 water pump is engineered with advanced components for reliable performance in demanding industrial settings. Below are its standout technical features:

-

Precision Engineering: Designed with tight tolerances to ensure efficient coolant flow and consistent engine cooling.

-

High-Grade Materials: Built from durable metals that resist corrosion and wear, extending the pump's lifespan.

-

Optimized Impeller Design: Features an advanced impeller shape that maximizes fluid circulation for improved engine temperature control.

-

Thermal Stability: Engineered to function efficiently even under high-temperature conditions, ensuring continuous operation without overheating.

Benefits

The unique design of the water pump 1376005 for Hyster provides a range of advantages beyond standard performance. Here are the key benefits:

-

Improved Engine Efficiency: Keeps the engine at an optimal temperature, reducing energy loss and boosting overall machine performance.

-

Longer Equipment Lifespan: With durable materials and advanced engineering, it reduces wear on engine components, extending their operational life.

-

Minimal Downtime: Reduces the overheating risk, helping keep machinery running smoothly and minimizing operational interruptions.

-

Enhanced Reliability: Designed for harsh industrial conditions, ensuring consistent performance in even the most demanding applications.

Symptoms of a Faulty Water Pump

If left unaddressed, a malfunctioning water pump can lead to severe engine problems. Recognizing the signs early can prevent costly damage.

-

Overheating Engine: When the water pump fails, coolant flow is reduced, causing the engine to overheat quickly.

-

Coolant Leaks: A damaged water pump often leaks coolant, leaving noticeable puddles under your forklift or vehicle.

-

Unusual Noises: Grinding or squealing noises may indicate worn bearings inside the water pump, signaling impending failure.

-

Steam from the Radiator: A failing water pump can cause the engine to overheat, resulting in steam escaping from the radiator.

-

Fluctuating Temperature Gauge: A faulty water pump may cause erratic temperature readings as the coolant flow becomes inconsistent.

Recommended Use/Applications

-

Forklifts: Ensures efficient cooling during heavy-duty forklift operations in industrial environments.

-

Warehouses: Maintains optimal engine temperature for machinery used in warehouse material handling.

-

Construction Equipment: Supports cooling systems in construction machinery running for extended periods.

-

Agricultural Machinery: Helps regulate engine temperature in agricultural vehicles during field operations.

| Model | Engine | Required | Notes |

| HYSTER S30XLB010 | VA | 1 | |

| HYSTER S40XLA187 | VA | 1 | |

| HYSTER S50XLA187 | VA | 1 | |

| HYSTER S60XLC187 | VA | 1 | |

| HYSTER H25XLC001 | VA | 1 | |

| HYSTER H30XLC001 | VA | 1 | |

| HYSTER H35XLC001 | VA | 1 | |

| HYSTER H40XLA177 | VA | 1 | |

| HYSTER H40XLC177-MAZDA | VA | 1 | |

| HYSTER H45XLC177-MAZDA | VA | 1 | |

| HYSTER H50XLA177 | VA | 1 | |

| HYSTER H50XLB177 | VA | 1 | |

| HYSTER H50XLC177-MAZDA | VA | 1 | |

| HYSTER H55XLB177 | VA | 1 | |

| HYSTER H55XLC177-MAZDA | VA | 1 | |

| HYSTER H60XLB177 | VA | 1 | |

| HYSTER H60XLC177-MAZDA | VA | 1 | |

| HYSTER S25XLB010 | VA | 1 | |

| HYSTER S35XLB010 | VA | 1 | |

| HYSTER S40XLB187 | VA | 1 | |

| HYSTER S40XLC187 | VA | 1 | |

| HYSTER S45XLA187 | VA | 1 | |

| HYSTER S45XLC187 | VA | 1 | |

| HYSTER S50XLB187 | VA | 1 | |

| HYSTER S50XLC187 | VA | 1 | |

| HYSTER S55XLA187 | VA | 1 | |

| HYSTER S55XLB187 | VA | 1 | |

| HYSTER S60XLA187 | VA | 1 | |

| HYSTER S60XLB187 | VA | 1 |

Application: Forklift

| Model | Serial Prefix | Engine/Power Unit | Category | Make |

| S30XL | B010 | VA | COOLING | HYSTER |

| H40XL | A177 | VA | COOLING | HYSTER |

| H50XL | A177 | VA | COOLING | HYSTER |

| S25XL | B010 | VA | COOLING | HYSTER |

| S35XL | B010 | VA | COOLING | HYSTER |

| S40XL | B187 | VA | COOLING | HYSTER |

| S50XL | B187 | VA | COOLING | HYSTER |

| S55XL | B187 | VA | COOLING | HYSTER |

| S60XL | B187 | VA | COOLING | HYSTER |

| S40XL | A187 | VA | COOLING | HYSTER |

| S50XL | A187 | VA | COOLING | HYSTER |

| S60XL | C187 | VA | COOLING | HYSTER |

| H40XL | C177 | VA | COOLING | HYSTER |

| H45XL | C177 | VA | COOLING | HYSTER |

| H50XL | B177 | VA | COOLING | HYSTER |

| H50XL | C177 | VA | COOLING | HYSTER |

| H55XL | B177 | VA | COOLING | HYSTER |

| H55XL | C177 | VA | COOLING | HYSTER |

| H60XL | B177 | VA | COOLING | HYSTER |

| H60XL | C177 | VA | COOLING | HYSTER |

| S40XL | C187 | VA | COOLING | HYSTER |

| S45XL | A187 | VA | COOLING | HYSTER |

| S45XL | C187 | VA | COOLING | HYSTER |

| S50XL | C187 | VA | COOLING | HYSTER |

| S55XL | A187 | VA | COOLING | HYSTER |

| S60XL | A187 | VA | COOLING | HYSTER |

| H25XL | C001 | VA | COOLING | HYSTER |

| H30XL | C001 | VA | COOLING | HYSTER |

| H35XL | C001 | VA | COOLING | HYSTER |

Frequently Asked Questions

What are the signs of a failing water pump?

A faulty pump often causes engine overheating, coolant leaks, unusual noises, and fluctuating temperature gauge readings. If you notice these symptoms, inspect the pump immediately to avoid further damage.

How long does a typical water pump last in industrial equipment?

The lifespan of a water pump can vary depending on usage and maintenance, but most last between 60,000 and 90,000 miles or several years in industrial applications. Regular inspections help extend its life.

Can a water pump failure damage the engine?

Yes, if the pump fails, it can cause the engine to overheat, potentially leading to severe engine damage, such as a blown head gasket or warped engine components.

What type of coolant should be used with this pump?

Always use the manufacturer-recommended coolant for your equipment to ensure optimal performance and longevity of the cooling system. Mixing coolant types can lead to corrosion or reduced efficiency.

How often should the water pump be inspected?

It's recommended to check the pump during routine maintenance or whenever you notice unusual engine behavior, such as overheating or coolant loss.

Is it necessary to replace the 1376005 water pump with the timing belt?

In many cases, it's wise to replace both simultaneously since they often wear similarly, and access to the pump requires removing the timing belt.

Can a leaking water pump be repaired, or does it need replacement?

Replacing it with a leaking water pump is usually better, as leaks often indicate internal damage that could worsen over time.

Frequently Bought Together

Are you gearing up to enhance the cooling and operational efficiency of your forklifts? We provide a selection of parts that perfectly complement the water pump, ensuring your equipment is always running at its best. Check out these vital components to round out your maintenance needs:

Questions and Answers

Product Reviews

Customers Who Bought This Item Also Bought

-

$14.31 THERMOSTAT/GASKET 326792 for Hyster SKU: 326792

-

$10.67 RADIATOR HOSE 300841 for Hyster SKU: 300841

-

$13.41 RADIATOR HOSE 333032 for HYSTER SKU: 333032

-

$12.16 RADIATOR HOSE (LOWER) J15-15005 SKU: J15-15005

-

$12.98 981885 : FAN BELT for HYSTER SKU: 981885

-

$2.79 326798 GASKET - WATER PUMP SKU:

Loading... Please wait...

Loading... Please wait...