- Home

- Forklift Parts

- Braking & Drive Axle

- Wheel Cylinders

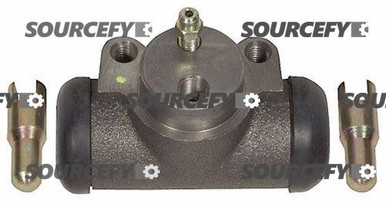

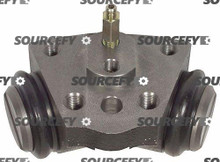

- WHEEL CYLINDER C52-11224-52 for TCM

Wheel Cylinder C52-11224-52 for TCM

Category: Wheel Cylinders

Product Description

The C52-11224-52 wheel cylinder plays a crucial role in TCM forklift braking systems. It transforms hydraulic pressure into mechanical force, pushing brake shoes against the drum, which helps stop the forklift effectively. Many readers may need to realize how vital regular wheel cylinder maintenance is in preventing brake failure. Brake systems rely on precise hydraulic movements; even small leaks or damage in the cylinder can significantly reduce stopping power.

The wheel cylinder C52-11224-52 for TCM is precisely engineered to handle high pressure while maintaining durability over time. It’s made from corrosion-resistant materials to ensure long-lasting performance under heavy-duty use. Replacing the wheel cylinder when necessary can maintain optimal forklift safety and reduce the risk of costly repairs. Understanding how hydraulic brake systems work helps extend forklift life and ensures smooth, safe operation in industrial environments.

|

Cross Reference |

52-11224-52000, TCMC-52-11224-52000, TCC-52-11224-52000, C521122452000, TC C-52-11224-52000, TCC521122452000, TC C521122452000, TCM C-52-11224-52000, TCMC521122452000, TCM C521122452000 |

Product Specifications

|

Part Type |

Wheel Cylinder |

|

Model Number |

C52-11224-52 |

|

Make |

TCM |

|

Condition |

New |

|

Warranty |

12 months |

Wheel Cylinder C52-11224-52 for TCM

Features

The C52-11224-52 wheel cylinder for TCM forklifts is engineered to enhance brake system efficiency through advanced hydraulic technology. Here are some unique technical features:

-

Precision Hydraulic Control: The cylinder ensures accurate control over hydraulic pressure, enhancing braking performance.

-

High-Pressure Endurance: They are built to withstand extreme hydraulic pressure, making them reliable for heavy-duty operations.

-

Corrosion-Resistant Material: It is made from specially treated materials to prevent rust and corrosion, extending the product's lifespan.

-

Sealed Piston Design: The sealed piston helps reduce fluid leakage, ensuring smooth operation and less maintenance.

Benefits

Using the C52-11224-52 wheel cylinder improves forklift performance and safety, offering multiple operational advantages:

-

Improved Brake Response: Faster hydraulic transfer means quicker brake response, enhancing forklift safety.

-

Increased Durability: Corrosion resistance and high-pressure tolerance make the cylinder last longer in harsh environments.

-

Reduced Maintenance Downtime: With a sealed design, less fluid leakage translates into fewer maintenance stops, keeping your operations running smoothly.

-

Enhanced Load Handling: Precise braking ensures stable handling of heavy loads, improving overall forklift performance.

Symptoms of a Faulty Wheel Cylinder

A faulty wheel cylinder can significantly affect a forklift's braking performance and safety. Identifying early symptoms helps prevent further damage.

-

Spongy Brake Pedal Feel: A faulty wheel cylinder can cause a soft, spongy brake pedal, leading to delayed or ineffective braking.

-

Brake Fluid Leaks: Leaking brake fluid around the wheels strongly indicates a malfunctioning wheel cylinder.

-

Uneven Brake Wear: Unequal wear on brake shoes can signal that the wheel cylinder isn't applying pressure evenly.

-

Reduced Braking Efficiency: A failing cylinder causes inconsistent braking, making it harder to stop the forklift safely.

-

Excessive Brake Pedal Travel: A faulty wheel cylinder increases the distance required to press the pedal before the brakes engage.

Recommended Use/Applications

-

Forklifts: Ensures effective braking for heavy load handling in warehouses.

-

Material Handling: Provides reliable braking in industrial material transport vehicles.

-

Logistics: Ensures smooth braking in vehicles carrying large cargo loads.

-

Construction Vehicles: Maintains safe operations in rough terrain with heavy-duty machinery.

-

Pallet Jacks: Enhances braking precision for safe handling of loaded pallets.

-

Agricultural Equipment: Supports safe operation in farm machinery with hydraulic brake systems.

Frequently Asked Questions

How do I know if my wheel cylinder needs replacement?

Look for symptoms like spongy brake pedals, fluid leaks, or uneven brake wear. If your braking feels less responsive, inspecting the cylinder is a good idea.

Can I use this wheel cylinder C52-11224-52 for TCM with different forklift models?

It's explicitly designed for TCM forklifts. However, always verify the part number and specifications to ensure compatibility with your model.

What materials are used in this wheel cylinder?

The cylinder is crafted from high-quality, corrosion-resistant materials, making it durable in industrial and heavy-duty applications.

How often should I check the wheel cylinder for issues?

Regular inspections during routine maintenance are recommended, primarily if your forklift operates in harsh conditions or under heavy loads.

What happens if I ignore a faulty wheel cylinder?

A faulty wheel cylinder can reduce braking efficiency, increasing the risk of brake failure. It's crucial to replace it promptly to maintain forklift safety.

Does the cylinder affect other parts of the braking system?

Yes, a malfunctioning cylinder can impact brake shoes and drums, causing uneven wear and compromising overall brake performance.

Can a leaky wheel cylinder be repaired, or does it need replacement?

Minor leaks might be repaired, but significant damage or wear typically requires a complete cylinder replacement to ensure proper function.

Frequently Bought Together

Are you aiming to fully refurbish your forklift’s braking system? Explore our comprehensive range at Sourcefy, where we provide a variety of parts that enhance and complement the wheel cylinder. Purchase these crucial components to guarantee your forklift operates safely and efficiently:

Questions and Answers

Product Reviews

Customers Who Bought This Item Also Bought

-

$15.36 EMERGENCY BRAKE CABLE 36530-1K200 for Nissan SKU: 36530-1K200

Loading... Please wait...

Loading... Please wait...